What Are Concrete Cover Blocks?

In any reinforced concrete structure, durability and safety are critical. While TMT bars are well-known for their strength and reinforcement, one small yet essential building component material often goes unnoticed are Concrete Cover Blocks.

Concrete cover blocks may seem like a minor part of construction, but they play a huge role in ensuring the long-term strength and durability of structures. In this blog, we’ll explore what cover blocks are, why they are important, their types, sizes, and how they are used in real-world construction.

What Are Concrete Cover Blocks?

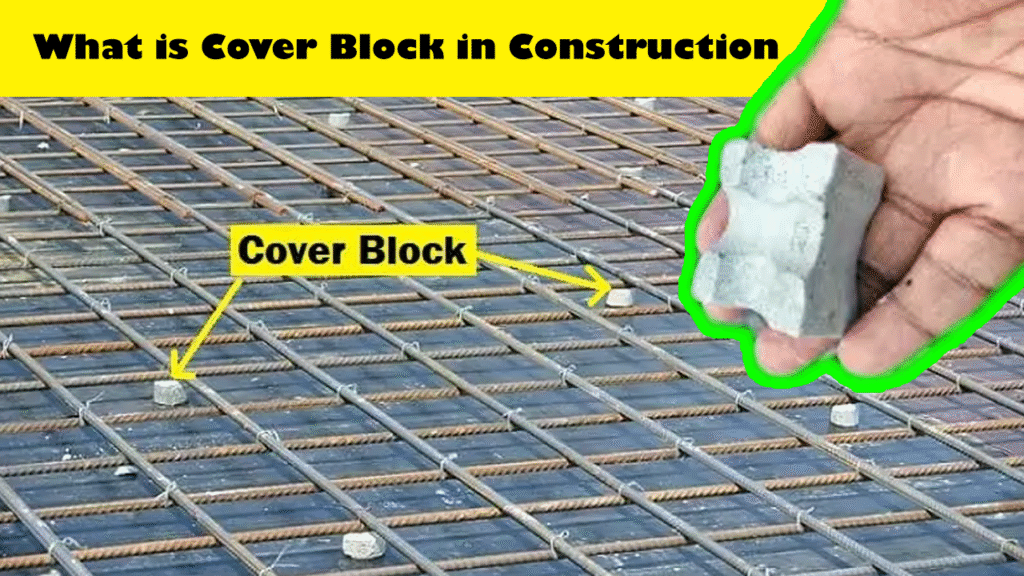

Concrete cover blocks, also known as spacer blocks, are small concrete pieces placed between the shuttering (formwork) and the reinforcement bars (TMT bars). Their main purpose is to ensure the correct spacing between steel bars and the outer surface of the concrete.

This spacing, called “concrete cover,” protects steel from corrosion, ensures proper bonding with concrete, and maintains structural strength over time.

Why Are Concrete Cover Blocks Important?

Concrete cover blocks serve several vital purposes:

- Protect TMT bars from corrosion

- Ensure fire resistance by maintaining correct cover depth

- Keep reinforcement bars in place during concreting

- Ensure proper compaction of concrete around bars

- Help in maintaining design accuracy and structural integrity

Without proper cover blocks, even high-quality TMT bars may fail prematurely due to corrosion, exposure to heat, or poor placement.

Types of Concrete Cover Blocks

Cover blocks come in various materials, but concrete blocks are the most preferred due to their compatibility with RCC structures. Here are the common types:

1. Concrete Cover Blocks

Made from a mix of cement, aggregates, and admixtures, they are strong and durable, ideal for all types of structures.

2. Plastic Cover Blocks

Lightweight and used in non-critical areas, but not as strong or durable as concrete ones.

3. Fiber-Reinforced Blocks

Used for high-end applications where additional strength and precision are required.

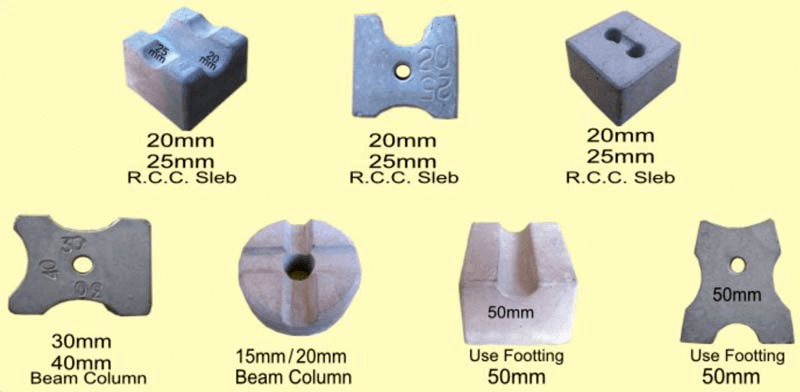

Standard Sizes of Cover Blocks

The size of a concrete cover block depends on where it is used in a structure. Common sizes include:

- 20 mm – For slabs

- 25 mm – For beams

- 40 mm to 50 mm – For columns and footings

- 75 mm or more – For raft foundations and large structures

Choosing the right size ensures that the TMT bars receive adequate protection according to structural requirements.

Applications of Concrete Cover Blocks

Cover blocks are used in almost every reinforced concrete structure:

- Residential buildings (slabs, beams, columns)

- Commercial and industrial structures

- Bridges and flyovers

- Foundations and basements

- Water tanks and retaining walls

Anywhere reinforcement is used, cover blocks are a must for ensuring safety and longevity.

Why Choose Sunvik Steels for Cover Blocks?

At Sunvik Steels Pvt Ltd, we believe in offering complete structural solutions to our Sunvik Customers. That’s why we provide concrete cover blocks with multi dimension sizes i.e in 20mm,25mm,40mm & 50mm All in One,which can be used at any place of the structure and are provided free of cost when you purchase Sunvik TMT bars..

This not only ensures that you receive the best reinforcement steel but also the essential accessories required for quality construction — all in one place.

Sunvik cover blocks are:

- Made from high-strength concrete

- Available in standard sizes

- Designed to meet IS standards

- Compatible with all grades of Sunvik TMT bars

Final Thoughts

Concrete cover blocks are the unsung heroes of reinforced concrete construction. They protect your investment by ensuring that the TMT bars you rely on perform at their best for decades. Whether you’re a builder, engineer, or homeowner, always ensure proper use of cover blocks for safe and durable structures.

And if you’re looking for high-quality TMT bars and reliable concrete cover blocks, Sunvik Steels Pvt Ltd has you covered. With every purchase of Sunvik TMT bars, you receive free concrete cover blocks, making your construction smarter, safer, and more economical.

Visit https://sunviksteels.com to know more or connect with our team today.

FAQs

1. What are concrete cover blocks made of?

They are made of cement, sand, and aggregate, similar to regular concrete, offering strength and durability.

2. Can I use plastic cover blocks instead of concrete ones?

Plastic cover blocks are suitable for small projects but not recommended for heavy or long-lasting structures.

3. Are cover blocks required in all RCC structures?

Yes, cover blocks are essential for every RCC structure to protect reinforcement bars from corrosion and damage.

4. How many cover blocks are needed for a building?

It depends on the structure’s size and complexity. An engineer or site supervisor can estimate the required quantity accurately.

5. Does Sunvik Steels offer cover blocks for free?

Yes, Sunvik Steels provides high-quality concrete cover blocks free of cost with the purchase of SUNVIK TMT bars.