Benefits of Choosing MS Welded Wire Mesh

When it comes to industrial and infrastructure projects, strength, stability, and safety are the foundation of success. One material that consistently meets these demands is the MS (Mild Steel) Welded Wire Mesh. Whether used in construction, mining, or manufacturing, this versatile product offers reliability, cost-efficiency, and long-term performance.

In this blog, we’ll explore what MS Welded Wire Mesh is, its advantages, applications, and why industries around the world rely on it for high-performance results.

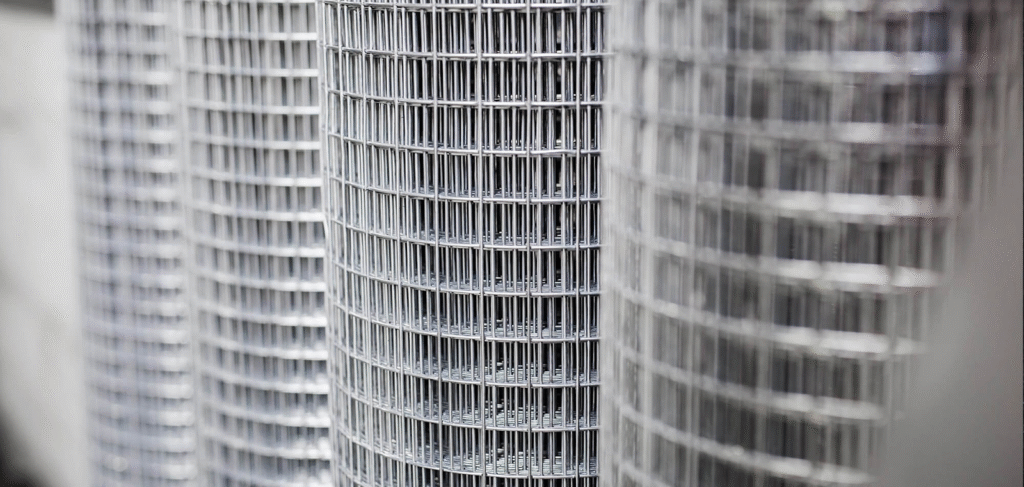

What Is MS Welded Wire Mesh?

MS Welded Wire Mesh is made by welding mild steel wires together at their intersections to form a grid-like pattern. This process creates a strong and rigid structure that can withstand both tension and compression.

The mild steel used in the mesh has low carbon content, which provides excellent ductility — allowing it to bend without breaking, making it ideal for reinforcement and structural applications.

MS Welded Wire Mesh comes in different wire diameters (from 2mm to 12mm) and mesh openings (from 25mm to 200mm), allowing customization based on project needs. It can also be galvanized or PVC-coated for better corrosion resistance, especially in humid or coastal environments.

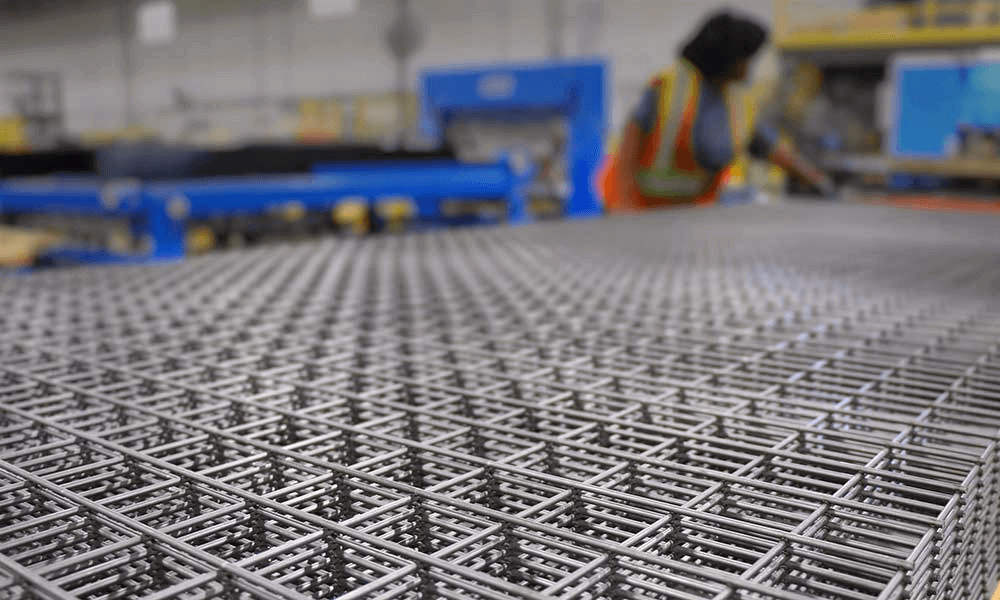

How MS Welded Wire Mesh Is Made

The production of MS Welded Wire Mesh involves several quality-controlled stages:

- Wire Drawing: High-quality mild steel rods are drawn into thin wires of desired thickness.

- Straightening & Cutting: The wires are straightened and cut to uniform lengths.

- Welding: The wires are welded at right angles using advanced automatic machines to ensure perfect alignment and strong joints.

- Finishing: The mesh may undergo galvanization, powder coating, or PVC coating to improve its resistance against corrosion and rust.

This automated manufacturing ensures uniform spacing, consistent strength, and high structural integrity, which are critical in industrial applications.

Key Benefits of Using MS Welded Wire Mesh

1. High Tensile Strength and Load-Bearing Capacity

The welded intersections make the mesh exceptionally strong and rigid. It can easily handle heavy loads, vibration, and pressure, making it suitable for flooring, reinforcement, and machinery guards in industrial setups.

2. Dimensional Accuracy and Uniformity

Since the mesh is machine-welded, it provides precise spacing and uniform wire thickness, ensuring consistency in construction and structural reinforcement.

3. Resistance to Deformation

Unlike woven meshes, welded wire mesh doesn’t lose its shape under pressure. Its rigid structure makes it ideal for applications where dimensional stability is vital — such as retaining walls and factory partitions.

4. Corrosion Protection

When galvanized or PVC coated, the mesh gains long-term corrosion resistance, making it suitable for outdoor and marine environments. This protective layer prevents oxidation, ensuring a longer service life.

5. Cost-Effective and Efficient

MS Welded Wire Mesh offers excellent strength-to-cost value. It reduces material wastage, minimizes labor during installation, and cuts down project timelines — making it an economical choice for industrial and commercial applications.

6. Enhanced Safety and Security

In industrial environments, safety is non-negotiable. Welded wire mesh acts as a protective barrier in warehouses, machinery enclosures, and perimeter fencing, helping prevent workplace accidents.

7. Easy Installation and Customization

The mesh is lightweight, easy to cut, and install on-site. Custom sheet sizes can be fabricated according to project requirements, minimizing assembly time and material waste.

Applications of MS Welded Wire Mesh in Industrial Projects

`

The versatility of MS Welded Wire Mesh makes it indispensable across multiple sectors:

1. Construction Industry

- Reinforcement in concrete slabs, walls, beams, and columns.

- Used for retaining walls, walkways, and precast panels.

- Structural support in bridges and tunnels.

2. Manufacturing and Warehousing

- Protective cages for machinery.

- Partitions between work zones.

- Industrial flooring with mesh reinforcement.

3. Agriculture and Poultry

- Animal cages, aviaries, and crop protection fences.

- Boundary fencing for farms and storage yards.

4. Mining and Petrochemical

- Used for shaft linings, rock reinforcement, and safety barricades.

- Ideal for heavy-duty filtration and screening purposes.

5. Transportation and Infrastructure

- Road dividers, flyover reinforcements, and bridge fencing.

- Security barriers in metro stations and airports.

6. Energy and Utilities

- Enclosures for transformers, power stations, and pipelines.

These applications highlight how MS Welded Wire Mesh plays a key role in strengthening infrastructure and ensuring operational safety.

MS Welded Wire Mesh vs Traditional Reinforcement Bars

| Parameter | MS Welded Wire Mesh | Traditional Reinforcement Bars |

| Installation Speed | Fast and easy (prefabricated sheets) | Time-consuming (manual tying of bars) |

| Material Wastage | Minimal | High |

| Cost Efficiency | More economical for large surface areas | Higher cost due to labor and material usage |

| Structural Uniformity | Consistent and precise spacing | Depends on manual placement accuracy |

| Flexibility | Easy to transport, handle, and cut | Limited flexibility during installation |

| Corrosion Resistance | High (especially when coated or galvanized) | Moderate, depending on exposure and quality |

This comparison clearly shows that MS Welded Wire Mesh offers superior efficiency, precision, and cost advantages over traditional reinforcement methods.

Tips for Selecting the Right Welded Wire Mesh

- Choose the Right Gauge: Thicker wires offer higher strength but may reduce flexibility.

- Select Appropriate Coating: For outdoor use, galvanized or PVC-coated mesh is recommended.

- Consider Mesh Size: Smaller openings provide more reinforcement, while larger ones are ideal for fencing.

- Buy from Certified Manufacturers: Ensure the product meets IS (Indian Standards) and other quality certifications.

Why Choose Sunvik Steels Pvt Ltd

At Sunvik Steels Pvt Ltd, we are committed to delivering high-quality, durable, and precisely engineered steel products. Our MS Welded Wire Mesh is manufactured using advanced technology, ensuring perfect welds, superior strength, and long-lasting performance.

We serve industries across construction, manufacturing, and infrastructure with a focus on quality, reliability, and customer satisfaction.

Visit: https://sunviksteels.com/

Contact Sunvik Steels Pvt Ltd today to get a quote or discuss your project requirements.

Frequently Asked Questions (FAQs)

1. Is MS Welded Wire Mesh suitable for outdoor applications?

Yes, when galvanized or PVC coated, it performs excellently in outdoor and humid environments.

2. Can I get custom sizes for industrial projects?

Yes, manufacturers like Sunvik Steels Pvt Ltd offer customizable mesh sizes, thicknesses, and coatings.

3. How does welded mesh compare to woven mesh?

Welded mesh offers greater rigidity, strength, and dimensional stability compared to woven mesh.

4. What are the maintenance requirements?

Minimal. A good-quality coated mesh requires little to no maintenance over its lifespan.

5. What industries use welded wire mesh the most?

Construction, mining, petrochemical, manufacturing, agriculture, and power sectors use it extensively.

Final Thoughts

MS Welded Wire Mesh is one of the most versatile, durable, and cost-effective materials in modern industrial construction. Its strength, stability, and adaptability make it a top choice for reinforcing and protecting industrial structures.

When you choose Sunvik Steels Pvt Ltd, you’re investing in superior quality, proven performance, and long-term reliability. Whether you’re building, fencing, or reinforcing, Sunvik’s MS Welded Wire Mesh ensures strength that lasts for years.

Get in touch with Sunvik Steels Pvt Ltd today to explore our full range of steel and wire products.

Visit: https://sunviksteels.com/