What Is Cold Dip Binding Wire

In construction and industrial projects, strength and durability are not defined only by large materials like cement and steel bars. Small components, such as binding wire, play an equally important role in ensuring structural stability and long-term performance. One such essential material is Cold Dip Binding Wire.

Cold dip binding wire is widely used because it offers a reliable balance of strength, flexibility, and corrosion resistance. From tying reinforcement bars in buildings to securing fencing and industrial materials, this wire has become a preferred choice across multiple industries.

This blog explains what cold dip binding wire is, how it is made, why it is preferred, where it is used, and how to choose the right quality for your project.

What Is Cold Dip Binding Wire?

Cold Dip Binding Wire is a steel wire coated with zinc using a cold galvanizing process. In this method, a zinc-rich compound is applied to the wire at normal temperatures rather than dipping it into molten zinc.

The zinc coating forms a protective layer that shields the steel from moisture, air, and chemicals that cause rust. This makes the wire more durable than plain mild steel wire while remaining flexible and easy to use.

Cold dip binding wire is commonly supplied in coils and is available in different gauges to suit various applications.

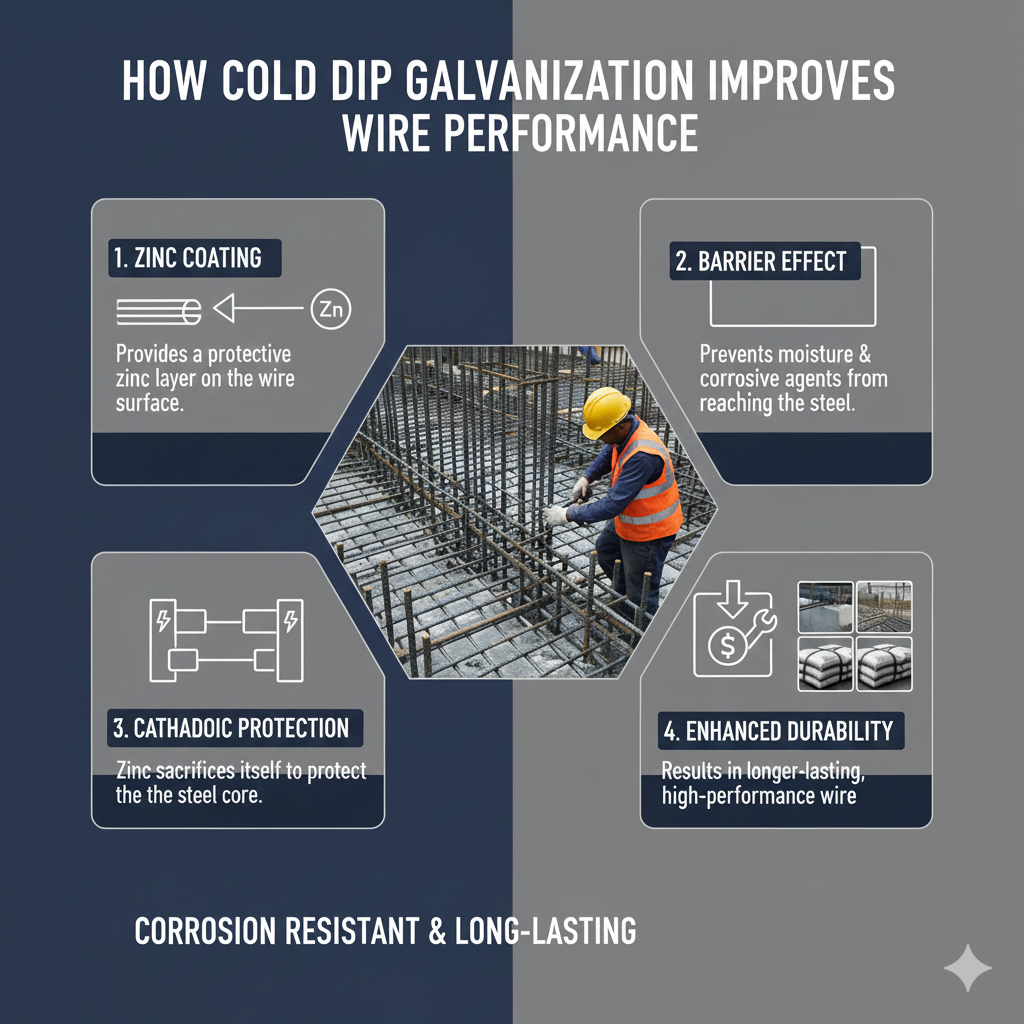

How Cold Dip Galvanization Improves Wire Performance

Cold dip galvanization plays a key role in the wire’s performance. The zinc layer:

- Acts as a barrier against corrosion

- Extends the life of the wire

- Reduces maintenance and replacement costs

- Improves resistance in humid and outdoor environments

While it may not be as thick as hot-dip galvanization, cold dip coating provides sufficient protection for most construction and general-purpose uses.

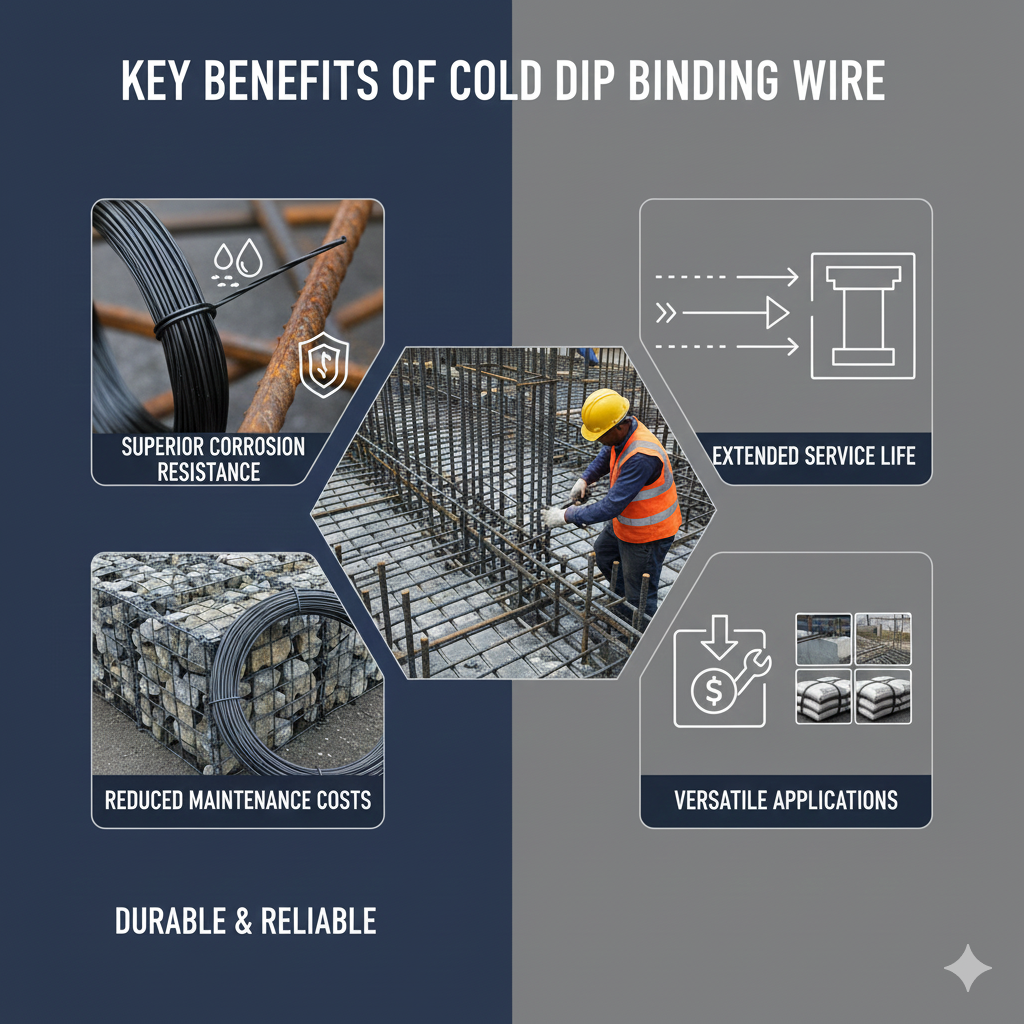

Key Benefits of Cold Dip Binding Wire

1. Strong Corrosion Resistance

Cold dip binding wire performs well in environments where moisture, cement slurry, and weather exposure are common. The zinc coating slows down rust formation, helping the wire maintain its strength over time.

2. High Tensile Strength

Despite its thin appearance, cold dip binding wire offers excellent tensile strength. It holds reinforcement bars firmly in place, ensuring that the structure maintains its intended shape during concrete pouring.

3. Excellent Flexibility

The wire is easy to twist, bend, and tie without snapping. This flexibility helps workers achieve tight and secure bindings quickly, improving on-site efficiency.

4. Longer Working Life

Compared to untreated binding wire, cold dip binding wire lasts longer and performs better in demanding conditions. This reduces the need for frequent replacements.

5. Smooth Surface Finish

The smooth zinc-coated surface makes handling easier and reduces the risk of cuts or abrasions during work.

6. Cost-Effective Choice

Cold dip binding wire offers corrosion resistance at a reasonable cost, making it an economical option for both small and large projects.

Applications of Cold Dip Binding Wire

1. Reinforcement Binding in Construction

The most common use of cold dip binding wire is tying reinforcement bars in RCC structures such as:

- Residential buildings

- Commercial complexes

- Bridges

- Slabs and columns

It ensures rebars stay in the correct position until concrete sets.

2. Fencing and Wire Mesh Binding

Cold dip binding wire is used to tie barbed wire, chain-link fencing, and welded wire mesh. Its corrosion resistance makes it suitable for outdoor fencing installations.

3. Industrial and Fabrication Work

Industries use this wire for bundling rods, pipes, and fabricated components. It provides secure binding during storage and transportation.

4. Agricultural Applications

In farming, cold dip binding wire is used for:

- Supporting plants and creepers

- Repairing farm fencing

- Securing agricultural structures

Its durability makes it suitable for open-field conditions.

5. Packaging and Material Bundling

Cold dip binding wire is also used in packaging heavy materials where strong tying is required without frequent breakage.

Cold Dip Binding Wire vs Plain Binding Wire

Cold dip binding wire offers several advantages over plain mild steel wire:

- Better resistance to rust

- Longer service life

- Improved durability

- Better performance in wet conditions

This makes it a more reliable option for professional construction and industrial use.

How to Choose the Right Cold Dip Binding Wire

When selecting cold dip binding wire, consider:

- Zinc coating quality

- Wire thickness and gauge

- Uniformity of coating

- Flexibility and tensile strength

- Supplier reputation

Choosing a trusted manufacturer ensures consistent quality and dependable performance.

Conclusion

Cold Dip Binding Wire may seem like a small component, but it plays a vital role in construction, industrial, and agricultural projects. Its corrosion resistance, strength, flexibility, and cost-effectiveness make it a practical and reliable choice. Using high-quality cold dip binding wire ensures better structural integrity, longer life, and smoother project execution.

Buy High-Quality Cold Dip Binding Wire from Sunvik Steels Pvt. Ltd.

If you are looking for durable, strong, and reliable Cold Dip Binding Wire, Sunvik Steels Pvt. Ltd. is a trusted name you can depend on. Their cold dip binding wire is manufactured with strict quality standards to ensure excellent corrosion resistance, consistent strength, and long-lasting performance.

Whether for construction, fencing, industrial use, or agriculture, Sunvik Steels offers binding wire solutions that meet professional requirements.

Visit their official website to learn more:

https://sunviksteels.com/

Customer Care Number: 07676104444

Choose Sunvik Steels for quality materials that help you build stronger and last longer.

Frequently Asked Questions (FAQs)

1. What is cold dip binding wire mainly used for?

It is mainly used for tying reinforcement bars, fencing, industrial binding, and agricultural applications.

2. How does cold dip binding wire differ from hot-dip wire?

Cold dip wire is coated using a zinc compound at normal temperatures, while hot-dip wire is coated by dipping in molten zinc.

3. Is cold dip binding wire suitable for outdoor use?

Yes, it performs well in outdoor and moderately corrosive environments.

4. Does cold dip binding wire rust?

It resists rust significantly better than plain wire, though proper storage further increases its lifespan.

5. Is it flexible enough for construction work?

Yes, it is designed to be flexible and easy to twist without breaking.

6. Can it be used for fencing repairs?

Yes, it is commonly used for tying and repairing fences and wire mesh.

7. What sizes are available in cold dip binding wire?

It is available in different gauges depending on application needs.

8. Is cold dip binding wire cost-effective?

Yes, it offers durability and corrosion resistance at a reasonable price.

9. How long does cold dip binding wire last?

With proper use, it can last many years in normal conditions.

10. Where can I buy reliable cold dip binding wire?

You can purchase high-quality cold dip binding wire from Sunvik Steels Pvt. Ltd. through their official website.