What Is GI Wire

In modern construction, agriculture, and industrial applications, GI wire (Galvanized Iron Wire) has become an essential material. Known for its strength, durability, and corrosion resistance, GI wire ensures long-lasting performance even in the toughest environments.

But what exactly is GI wire, how is it made, and why is it so widely used?

Let’s explore everything you need to know — from its manufacturing process to key advantages and real-world applications.

What Is GI Wire?

GI wire stands for Galvanized Iron Wire — a mild steel wire coated with a protective layer of zinc.

This zinc coating protects the wire from rust, corrosion, and environmental wear, making it ideal for outdoor and long-term use.

The galvanization process gives the wire:

- High corrosion resistance

- Tensile strength

- Extended lifespan

- Excellent binding and flexibility properties

Because of these properties, GI wire is used in fencing, construction, agriculture, power transmission, and many other sectors.

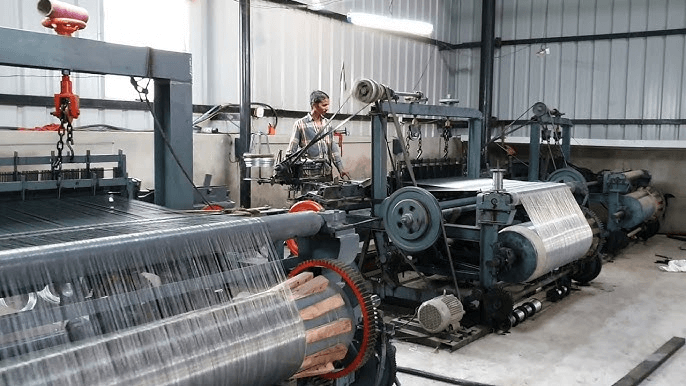

How GI Wire Is Made: The Manufacturing Process

The manufacturing of GI wire involves multiple steps to ensure quality, consistency, and durability:

- Wire Drawing:

High-quality low-carbon steel rods are drawn through dies to achieve the desired thickness. - Annealing:

The wire is heat-treated to enhance flexibility and reduce brittleness. - Surface Cleaning:

The drawn wire is cleaned through acid pickling to remove scales, rust, and impurities. - Galvanization:

The cleaned wire is coated with zinc using one of two methods:

- Hot-Dip Galvanization: The wire is dipped in molten zinc, forming a thick, durable, corrosion-resistant layer.

- Electro-Galvanization: Zinc is applied using an electric current for a smoother, thinner, and more uniform finish.

- Hot-Dip Galvanization: The wire is dipped in molten zinc, forming a thick, durable, corrosion-resistant layer.

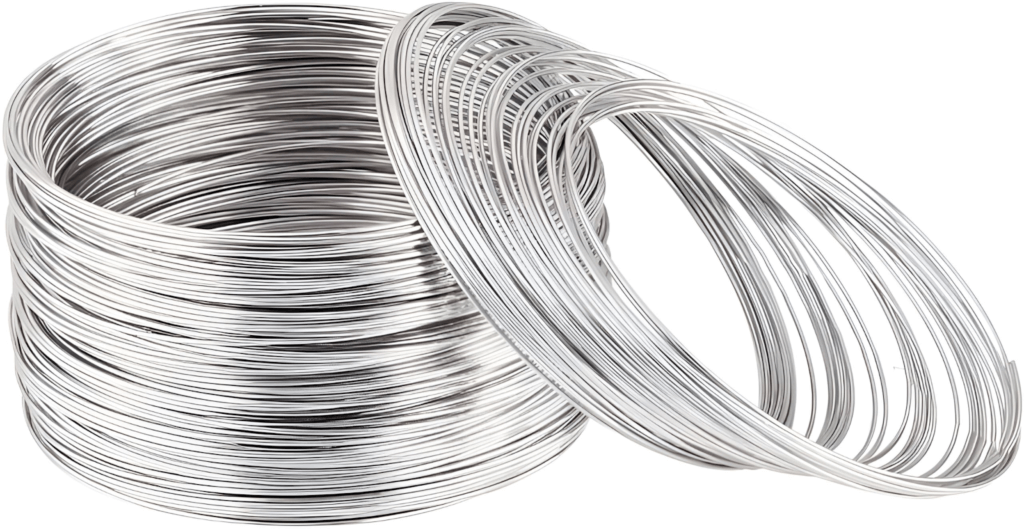

- Finishing & Coiling:

After coating, the wire is cooled, inspected, and wound into coils or pre-cut lengths for distribution.

Types of GI Wire and its Applications:

GI wire is classified based on galvanization method, thickness, and application.

1. Hot-Dip Galvanized Iron (HDGI) Wire

- Thick zinc coating (80–100 g/m² or more)

- Ideal for outdoor use and high-moisture environments

- Long-lasting and highly corrosion-resistant

2. Electro-Galvanized Iron (EGI) Wire

- Uniform zinc layer (around 10–30 g/m²)

- Smooth surface finish

- Suitable for indoor applications or temporary use

3. Soft Annealed GI Wire

- Extra flexibility

- Used in binding, packing, and agriculture

4. High-Tensile GI Wire

- Manufactured from high-carbon steel

- Offers excellent strength and used for fencing, power lines, and barbed wire

Applications of GI Wire

GI wire is one of the most versatile metal products — it plays a crucial role across various industries:

1. Construction Industry

- Binding and tying reinforcement bars (rebar)

- Scaffolding and support

- Structural reinforcement in concrete works

- Plastering and mesh frameworks

2. Fencing & Security

- Perimeter fencing around properties

- Barbed wire and chain-link fencing

- Boundary protection for factories, airports, and farms

3. Agriculture & Farming

- Crop protection and trellising

- Poultry cages and animal enclosures

- Supporting plant structures and greenhouse setups

4. Electrical & Power Distribution

- Earthing and grounding systems

- Power transmission lines

- Guy wires and cable supports

5. Industrial & Domestic Applications

- Wire mesh and sieves

- Packaging and bundling

- Handicrafts, hanging tools, and furniture fabrication

Advantages of GI Wire

GI wire is preferred over plain steel or other materials for several reasons:

1. Corrosion & Rust Resistance

Zinc coating acts as a shield against moisture and oxygen, preventing rust formation even in coastal or industrial areas.

2. Long Lifespan

Hot-dip galvanized wires can last 15–25 years, depending on environmental exposure, making them a cost-effective choice over time.

3. Superior Strength & Flexibility

GI wire offers high tensile strength and flexibility, allowing easy handling during construction or installation.

4. Low Maintenance

Once installed, GI wire requires minimal maintenance — no need for frequent repainting or coating.

5. Cost-Effective Solution

While slightly costlier than bare steel, its durability and low upkeep make it economically smarter in the long run.

6. Aesthetic Appearance

The shiny metallic surface gives a neat, clean, and professional look, especially in visible fencing or structural uses.

7. Eco-Friendly & Recyclable

Zinc and steel are both recyclable, making GI wire an environmentally responsible choice.

Why Choose Sunvik WirePro GI Wire?

At Sunvik Steels Pvt Ltd, we believe in delivering strength with sustainability.

Our GI wires are manufactured using state-of-the-art galvanizing technology, ensuring:

- Uniform zinc coating for enhanced corrosion resistance

- High tensile and yield strength

- Excellent ductility for easy usage

- Strict quality control as per IS 280 standards

Whether you need GI wire for construction, fencing, agriculture, or industrial purposes, Sunvik Wirepro provides customized solutions for all your project requirements.

FAQs About GI Wire

Q1. What makes GI wire different from normal steel wire?

Normal steel wire rusts easily. GI wire has a zinc coating that acts as a barrier against rust, extending its lifespan and strength.

Q2. Can GI wire be used for outdoor applications?

Yes, GI wire is perfect for outdoor use — especially the hot-dip galvanized type, which withstands rain, humidity, and sunlight for years.

Q3. Is GI wire available in different thicknesses?

Yes, GI wire comes in various gauges (SWG or BWG) — commonly from 8 to 20 — depending on your project’s requirements.

Q4. What is the lifespan of GI wire?

Typically, GI wire can last 10 to 25 years, depending on the galvanization thickness and environmental conditions.

Q5. Does Sunvik Steels provide customized GI wire?

Absolutely! Sunvik Steels offers GI wire in custom diameters, coatings, and coil sizes based on specific client needs.

Conclusion

GI wire has proven to be a reliable, versatile, and durable material for countless applications — from construction and agriculture to fencing and industrial uses.

Its corrosion resistance, strength, and low maintenance make it a top choice for builders and engineers worldwide.

Looking for high-quality GI Wire that delivers strength, reliability, and long-lasting performance?

Trust Sunvik Steels Pvt Ltd ,Wirepro Products— one of India’s leading manufacturers of premium galvanized products.

Visit Sunvik Steels Pvt Ltd to explore our GI wire range, request a quote, or get expert guidance for your next project.

Choose Sunvik GI Wire — where strength meets sustainability.