Advantages of Using GI Weld Mesh

In today’s construction and security landscape, reliability and long-term performance are more important than ever. Whether it is a residential project, commercial development, industrial facility, or security perimeter, choosing the right reinforcement and protection materials makes a huge difference in strength, safety, and durability.

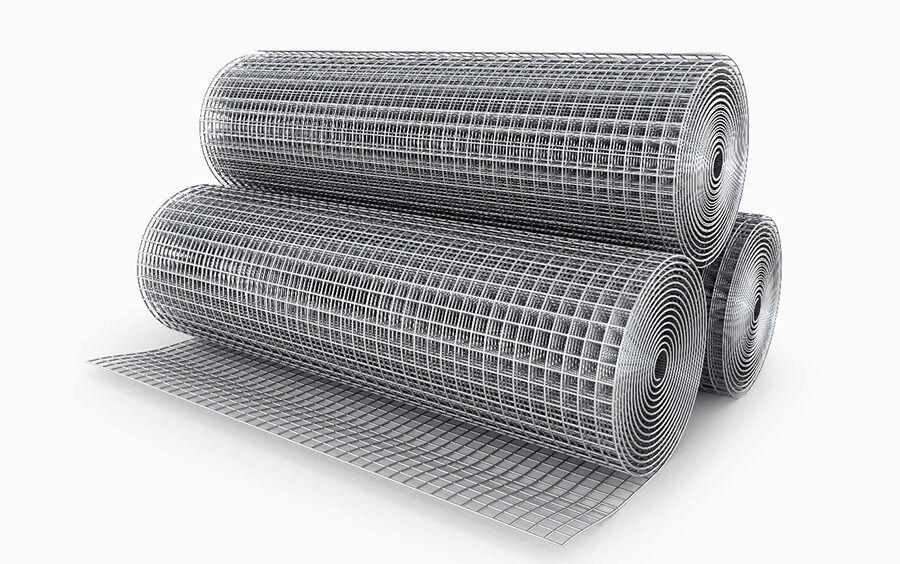

One material that has gained widespread acceptance across both construction and security applications is GI Weld Mesh. Manufactured using high-quality steel wires that are welded at accurate intersections and coated with a protective zinc layer (galvanization), GI Weld Mesh offers an ideal balance of strength, versatility, and cost efficiency.

This blog explores the major advantages of using GI Weld Mesh, focusing on how it enhances both construction quality and security infrastructure.

1. Superior Corrosion Resistance

The galvanization process is one of the biggest strengths of GI Weld Mesh. The zinc coating protects the steel wire from rust—even in challenging weather conditions. This makes GI Weld Mesh highly reliable for long-term use in construction sites, boundary protection systems, and outdoor installations.

Its rust-resistant nature also helps reduce maintenance costs and ensures the structure remains strong and safe for years.

2. High Structural Strength

GI Weld Mesh is manufactured through a precise welding process that results in:

- Uniform strength at every joint

- High load-bearing capacity

- Excellent stability under stress

In construction, this makes it an ideal choice for reinforcing concrete slabs, walls, footings, walkways, precast panels, and industrial flooring. Its consistent grid pattern distributes weight evenly, contributing to overall structural reliability.

3. Precision, Consistency, and Quality Assurance

Each sheet of GI Weld Mesh is produced with strict quality standards. This ensures:

- Accurate spacing between wires

- Consistent wire thickness

- Strong welding at every intersection

Such precision helps builders create cleaner structures with fewer weak points. Unlike manual tying systems, GI Weld Mesh eliminates human error and delivers predictable performance.

4. Faster and Easier Installation

Construction teams appreciate materials that save time without compromising strength. GI Weld Mesh offers exactly that. Because it comes in ready-made sheets with fixed spacing, it significantly reduces:

- On-site labor

- Installation time

- Need for manual binding

This helps speed up project timelines and reduces overall costs, especially in large-scale or tight-deadline projects.

5. Better Bonding With Concrete

The uniform grid design of GI Weld Mesh helps concrete grip securely during curing. This strong bonding reduces the chances of cracking and improves structural integrity. It is particularly effective in flooring, driveways, pavements, and load-bearing slabs where long-term performance matters.

6. Versatile Applications in Construction

GI Weld Mesh is used in a wide variety of construction applications due to its flexibility and high tensile strength. Common uses include:

- Reinforcing slabs, beams, and walls

- Precast concrete elements

- Road and pavement reinforcement

- Foundation structures

- Retaining walls

Its ability to maintain shape and stability makes it suitable for both lightweight and heavy-duty structural requirements.

7. Strong and Dependable for Security Applications

Beyond construction, GI Weld Mesh is widely used for security because of its strength and resistance to cutting and tampering. It is commonly used for:

- Perimeter fencing

- Industrial and factory boundaries

- Window and door guards

- Compound fences

- Agricultural property protection

- High-security enclosures

The galvanized coating ensures that even under outdoor exposure, the mesh remains dependable and strong.

8. Weather-Resistant and Durable

Whether exposed to sunlight, rain, dust, or temperature fluctuations, GI Weld Mesh maintains its form and strength. This durability makes it ideal for long-term installations where reliability cannot be compromised.

9. Cost-Effective Solution for Long-Term Use

Although GI Weld Mesh offers premium performance, it remains cost-effective due to:

- Lower maintenance costs

- Faster installation

- Reduced labor requirements

- Long lifespan

- Minimal replacement needs

This makes it a smart investment for builders, contractors, and security planners looking for value and durability.

10. Enhances Overall Project Safety

Strong reinforcement ensures safer buildings and secure boundaries. GI Weld Mesh reduces structural risks, prevents collapse during concrete pouring, provides safe perimeters, and enhances the overall safety of a project—both during and after construction.

Conclusion

GI Weld Mesh has become an essential material in modern construction and security systems. Its strength, corrosion resistance, precision manufacturing, and versatility make it a reliable choice for builders, contractors, and industries seeking durable reinforcement and dependable protection.

Whether you are working on a residential building, a commercial structure, or a security boundary, GI Weld Mesh ensures long-lasting performance and greater safety at every stage.

Looking for high-quality GI Weld Mesh that delivers strength, durability, and consistent performance?

Choose Sunvik Steels Pvt Ltd — a trusted name known for precision-engineered GI Weld Mesh and top-grade reinforcement solutions.

Explore premium construction and security products designed for long-term reliability.

Visit Sunvik Steels Pvt Ltd: https://sunviksteels.com/

Build stronger. Build safer. Build with Sunvik.

FAQs

1. What is GI Weld Mesh?

GI Weld Mesh is a steel wire mesh welded at intersections and coated with zinc for corrosion resistance. It is commonly used in construction and security installations.

2. Why is GI Weld Mesh preferred in construction?

Its strength, rust resistance, uniformity, and excellent bonding with concrete make it one of the best reinforcement materials available.

3. Is GI Weld Mesh suitable for security purposes?

Yes. Its strong welded structure and galvanized coating make it ideal for fencing, boundary protection, and high-security enclosures.

4. How long does GI Weld Mesh last?

With proper installation, GI Weld Mesh can last for many years due to its corrosion-resistant coating and solid steel base.

5. Is GI Weld Mesh cost-effective?

Absolutely. It reduces labor costs, installation time, and long-term maintenance, making it a budget-friendly choice for both construction and security.