GI Wire vs MS Wire

In the world of construction and industrial manufacturing, wires play an essential role in ensuring strength, safety, and durability. Among the various types available, GI (Galvanized Iron) Wires and MS (Mild Steel) Wires are the most widely used.

At first glance, both may seem similar, but they differ in their composition, properties, and applications. Understanding these differences can help you choose the right wire for your specific project—whether it’s construction, fencing, or industrial use.

What Is MS Wire?

MS Wire, or Mild Steel Wire, is made from low-carbon steel. It is known for its flexibility, strength, and ease of use. MS Wire is widely used in construction, manufacturing, and the automotive industry because it is easy to shape, weld, and handle.

However, one major drawback of MS Wire is that it is prone to rusting when exposed to moisture. To extend its life, it often requires painting, coating, or other forms of protection.

Common uses of MS Wire include:

- Binding in construction

- Making nails, bolts, and wire mesh

- Internal structural work

- Industrial manufacturing

What Is GI Wire?

GI Wire, short for Galvanized Iron Wire, is essentially Mild Steel Wire coated with zinc. The zinc coating is applied through a process called galvanization, which gives the wire excellent resistance to rust and corrosion.

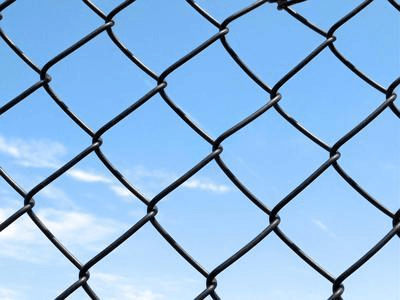

Because of this protective coating, GI Wire performs exceptionally well in outdoor environments and in applications exposed to rain, humidity, or chemicals.

Typical applications include:

- Fencing and boundary construction

- Agricultural and farming use

- Electrical grounding and earthing

- Outdoor construction and reinforcement

GI Wire vs MS Wire: The Key Differences

| Feature | GI Wire | MS Wire |

| Full Form | Galvanized Iron Wire | Mild Steel Wire |

| Material | Mild Steel with Zinc Coating | Low Carbon Steel |

| Rust Resistance | Excellent | Low |

| Durability | Long-lasting | Moderate |

| Maintenance | Very Low | Requires Coating or Paint |

| Cost | Slightly Higher | More Economical |

| Common Use | Fencing, Agriculture, Power Lines | Construction, Nails, Mesh |

When to Use GI Wire and When to Use MS Wire

If your project involves outdoor exposure, moisture, or changing weather conditions, GI Wire is the better choice because of its corrosion resistance and longevity. It’s perfect for fencing, outdoor construction, and electrical grounding.

If you’re working on indoor or short-term projects where the wire is not exposed to moisture, MS Wire is a more cost-effective option. It’s ideal for construction binding and manufacturing small components.

Which Wire Is Better for Construction?

Both wires serve their purpose in the construction industry.

- MS Wire is best suited for tying reinforcement bars and internal binding where rusting is not a concern.

- GI Wire is ideal for areas exposed to moisture, like fencing, outdoor reinforcement, and structural protection.

In today’s construction standards, GI Wire is often preferred for its strength, rust resistance, and long service life.

The Sustainability Factor

As the construction industry moves toward more sustainable practices, using materials that last longer and reduce waste has become essential. GI Wires, with their zinc coating, require less maintenance and fewer replacements over time, making them a more eco-friendly choice.

Choosing durable materials such as GI Wires and high-quality TMT Bars contributes to building structures that are both strong and environmentally responsible.

Why Choose Sunvik Steels Pvt. Ltd.?

Sunvik Steels Pvt. Ltd. is a trusted name in the steel industry, offering premium-quality steel products, including TMT Bars, GI Wires, and other steel materials. The company focuses on delivering strength, quality, and sustainability in every product.

Sunvik Steels stands out for its:

- Superior product strength and flexibility

- Excellent corrosion resistance

- Environment-friendly production process

- Consistent quality and customer support

Whether you’re building a home, an industrial project, or infrastructure, Sunvik’s steel solutions are designed to deliver long-term performance and reliability.

FAQs on GI Wire vs MS Wire

1. What is the main difference between GI and MS wires?

GI wire is coated with zinc to resist rust, while MS wire is plain mild steel and can rust when exposed to moisture.

2. Which wire lasts longer?

GI wire lasts significantly longer due to its galvanized coating, especially in outdoor conditions.

3. Can GI wire rust over time?

It’s rare, but over a long period and under extreme conditions, the zinc layer may wear off and expose the steel beneath.

4. Which is more affordable?

MS wire is more affordable initially, but GI wire provides better long-term value due to its low maintenance and longer life.

5. Can both be used in construction?

Yes. MS wires are used for internal works, while GI wires are used for fencing and outdoor construction.

Final Thoughts

Both GI and MS wires are important in construction and industrial use, but the right choice depends on your specific requirements. If you’re looking for a long-lasting, rust-resistant option for outdoor use, GI Wire is the best pick. For indoor or short-term needs, MS Wire is a more economical choice.

When quality and reliability matter, Sunvik Steels Pvt. Ltd. is your trusted partner. Their commitment to excellence ensures that every wire and TMT bar contributes to stronger, safer, and more sustainable structures.

Build Stronger with Sunvik Steels Pvt. Ltd.

Looking for durable and high-quality steel products for your next project?

Visit Sunvik Steels Pvt. Ltd. today to explore premium TMT Bars, GI Wires, and other steel solutions.

Strength. Quality. Sustainability.

That’s what you get when you build with Sunvik Steels.