What Is Stitch Wire

Stitch wire is one of those essential yet often overlooked materials that power many industries behind the scenes. From packaging to printing to large-scale manufacturing, stitch wire plays a crucial role in binding, sealing, and securing everyday products. Though small in size, its strength and durability make it indispensable for businesses that need reliable fastening solutions.

In this blog, we’ll explore what stitch wire is, how it’s made, where it is used, and why it matters. We’ll also connect its importance to industries like construction—where high-quality materials such as TMT bars remain just as essential.

What Is Stitch Wire?

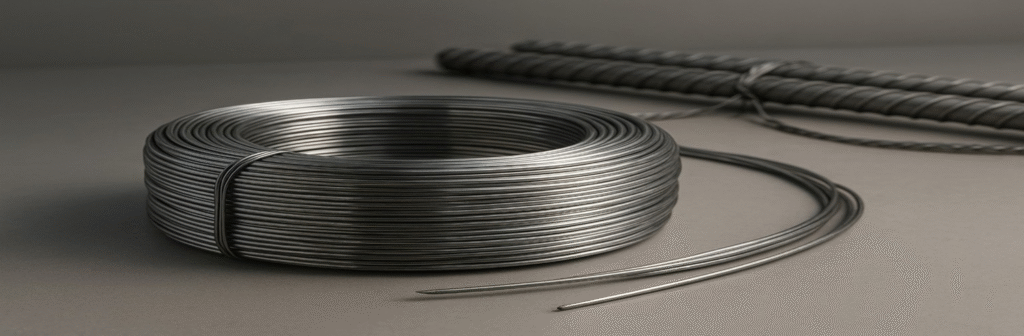

Stitch wire is a specially manufactured metal wire used for stitching, binding, and fastening materials together. It is made using high-quality low-carbon steel, which undergoes drawing and galvanizing processes to improve flexibility, tensile strength, and corrosion resistance.

The wire is supplied in spools or coils and can vary in:

- Thickness (gauge)

- Coating (galvanized, copper-coated, etc.)

- Tensile strength

- Type (flat stitch wire, round stitch wire)

It is primarily used in automated or manual stitching machines.

How Stitch Wire Is Manufactured

The production of stitch wire involves several key steps:

1. Wire Drawing

Raw steel rods are drawn through multiple dies to achieve the required thickness and smooth finish.

2. Annealing

The wire is heat-treated to improve ductility, allowing it to bend without breaking.

3. Coating

Different coatings improve durability:

- Galvanized coating protects against rust

- Copper coating improves electrical conductivity and bonding

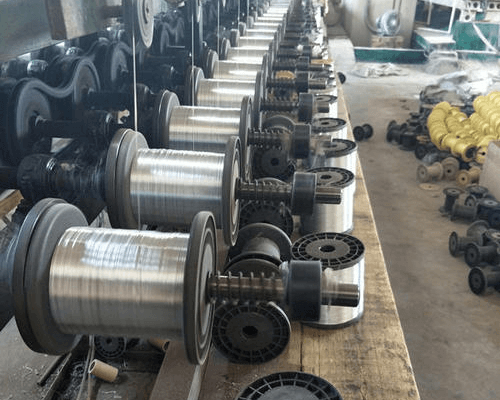

4. Spooling

The finished wire is neatly wound into spools, ready for use in high-speed binding or stitching machines.

Why Stitch Wire Is Important

Stitch wire is valued for its:

- High tensile strength – supports heavy-duty binding

- Flexibility – allows smooth operation in high-speed machines

- Corrosion resistance – suitable for long-term use

- Cost-effectiveness – affordable for mass production

Its reliability makes it essential in industries where secure fastening cannot be compromised.

Applications of Stitch Wire in Packaging and Binding

Stitch wire is widely used across various industries, especially where strong, durable binding is required. Here are the major applications:

1. Packaging Industry

One of the biggest consumers of stitch wire, the packaging sector uses it for:

- Carton box stitching

- Corrugated box manufacturing

- Heavy-duty packaging of industrial goods

- Sealing export-grade containers

Stitch wire ensures packaging remains firm even during rough handling, shipping, and stacking.

2. Printing and Bookbinding

In the printing industry, stitch wire is used for:

- Bookbinding

- Magazine stitching

- Notebook production

- Brochure and catalog binding

Round or flat stitch wires deliver clean, secure staples that last for years.

3. Stationery Manufacturing

Notebooks, registers, calendars, and office files are often stitched using wire for durability and neatness.

4. Industrial and Manufacturing Applications

Stitch wire is also used for:

- Securing mesh and screens

- Fastening insulation materials

- Attaching components in fabrication units

Its versatility makes it suitable for multiple machine-based operations.

5. Agricultural Packaging

Stitch wire is used for closing and securing agricultural packaging such as:

- Grain bags

- Seed sacks

- Fertilizer covers

It helps farmers and suppliers maintain safe storage and transport.

Importance of Quality in Stitch Wire

Just like construction materials, stitch wire quality matters. Low-quality wire may break, cause machine jams, or reduce the durability of packaging. High-grade stitch wire ensures:

- Smooth machine operations

- Longer life of stitched products

- Strong and reliable binding

- Minimum wastage and higher productivity

This concept of quality first applies across sectors—including construction, where the right TMT bar selection drastically impacts the strength and lifespan of structures.

Connecting the Dots: Quality Materials Matter Everywhere

Whether it’s stitch wire for packaging the foundation of long-lasting results lies in the quality of raw materials. Strong, reliable materials ensure safety, durability, and performance—something every industry depends on.

This is why companies like Sunvik Steels Pvt. Ltd. focus on delivering superior-grade stitch wire that meets industry standards and ensures long-term structural strength.

Call to Action for Sunvik Steels Pvt. Ltd.

If you are looking for high-strength, reliable, and high-performance stitch wire, Sunvik Steels Pvt. Ltd. offers some of the most trusted products in the industry.

Their stitch wires are known for:

- Exceptional strength and flexibility

- High corrosion resistance

- Earthquake-resistant properties

- Long-lasting performance

Build with confidence. Build with Sunvik Steels.

Visit sunviksteels.com to learn more or request a quote.

Frequently Asked Questions (FAQs)

1. What materials are used to make stitch wire?

Stitch wire is usually made from low-carbon steel and may include coatings like zinc or copper for added durability and corrosion resistance.

2. What is the difference between round and flat stitch wire?

Round stitch wire is used for traditional binding and stapling, while flat stitch wire is preferred for carton box stitching due to its broader holding surface.

3. Which industries commonly use stitch wire?

Major industries include packaging, printing, bookbinding, stationery manufacturing, agriculture, and general industrial fabrication.

4. Why does stitch wire need coating?

Coatings like galvanization prevent rust, enhance performance, and increase the lifespan of stitched products.

5. How does stitch wire relate to construction materials like TMT bars?

Both are essential raw materials in their respective industries. Quality stitch wire ensures strong binding, while quality TMT bars ensure strong structures—highlighting the importance of using premium materials.